Robot vacuums may look sleek and simple, but they're built from a wide variety of materials—each chosen for durability, function, and performance. From lightweight plastics like ABS to impact-resistant metals and precision electronics, every component plays a role in how your vacuum cleans your home.

In this guide, we’ll break down the materials used in robot vacuums—from the outer shell and wheels to sensors and internal circuitry. Whether you’re shopping for a new model or just curious about what’s under the hood, this article will help you understand how these materials affect your vacuum’s strength, safety, and lifespan.

Body Materials

-

Plastics

ABS (Acrylonitrile Butadiene Styrene) is a popular plastic used in the construction of robot vacuum bodies due to its durability and impact resistance. This material is also favored for its aesthetic flexibility, allowing manufacturers to design sleek, modern-looking devices that can withstand the rigors of daily use.

-

Polycarbonate

Known for its high impact resistance and strength, polycarbonate is another material commonly used in robot vacuums. Its robustness ensures that the vacuum can endure knocks and drops, making it a reliable choice for critical components.

-

Nylon

Nylon offers a unique combination of strength and flexibility, making it suitable for high-stress components within the vacuum. Its ability to withstand wear and tear without losing its structural integrity is essential for the longevity of these devices.

Which Materials Make a Robot Vacuum Last Longer?

When it comes to durability, not all robot vacuum materials are created equal. Here's what to look for if you want your device to stand the test of time:

-

ABS Plastic: Commonly used for outer shells due to its impact resistance and light weight. Great for daily use.

-

Polycarbonate: Even tougher than ABS, it’s ideal for high-impact areas or if you have pets or kids.

-

Rubber Brushes and Wheels: More flexible and tangle-free than nylon, especially good for pet hair and wooden floors.

-

Aluminum or Stainless Steel Parts: Used in structural areas like axles or internal supports. These resist bending and corrosion better than plastic.

-

Lithium-ion Batteries: Longer-lasting and quicker to charge compared to NiMH alternatives.

Choosing a robot vacuum with high-quality materials can lead to fewer repairs, longer lifespan, and better day-to-day performance.

Metal Components

-

Aluminum

Aluminum is often used for structural parts of robot vacuums due to its lightweight and corrosion-resistant properties. This metal helps in maintaining the device’s strength without adding unnecessary weight, enhancing maneuverability.

-

Stainless Steel

Stainless steel is the best choice for parts that need to be strong and resist corrosion. Its durability ensures that components like screws, shafts, and other critical parts remain functional over time, even with constant exposure to dust and debris.

Electronic Components

This part mostly consists of printed circuit boards (PCBs), which are further subdivided into two sections. They are:

-

Fiberglass

Fiberglass is commonly used as the substrate in PCBs due to its durability and non-conductive properties. It provides a stable platform for the electronic components, ensuring the vacuum’s reliability.

-

Copper

Copper is used for the electrical pathways on PCBs because of its excellent conductivity. This ensures efficient power distribution and signal transmission within the vacuum, which is crucial for its smooth operation.

Sensors

Without the sensors, we doubt if there would have been a robot vacuum to begin with. As such, sensors play an important role in the functionality of the robot vacuum cleaner. For this reason, we will discuss the components of the sensors your robot has.

First, we have infrared sensors. They are typically made of silicon and are used for obstacle detection. These sensors help the vacuum navigate around furniture and avoid collisions, enhancing its efficiency and preventing damage.

Secondly, we have the LIDAR components. They include laser diodes and receivers, which are made from semiconductor materials. These components provide precise mapping and navigation capabilities, allowing the vacuum to clean more effectively by understanding the layout of the space.

Batteries

Without the batteries, do you think your robot vacuum would function? No, it can’t. Therefore, you have to learn about this.

First, we have Lithium-ion batteries. We prefer them for their high energy density and long life. They provide the power needed for extended cleaning sessions and quick recharges, ensuring the vacuum is always ready to go. Notably, when you look at the batteries our Narwal Freo X Ultra or Freo X Plus has, you’ll notice they’re Lithium-ion batteries.

Secondly, there is the Nickel-Metal Hydride (NiMH). While less common, NiMH batteries are sometimes used due to their durability and cost-effectiveness. They offer a reliable power source for robot vacuums, though they generally have a shorter lifespan compared to lithium-ion batteries.

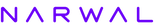

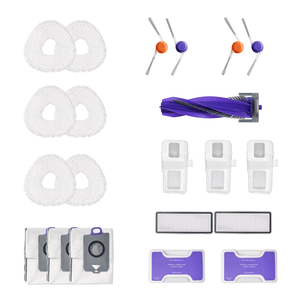

Cleaning Mechanisms

Now, these are what ensure the actual cleaning is happening. They include brushes and filters.

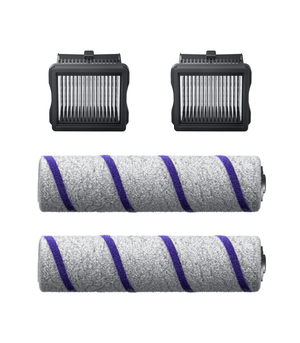

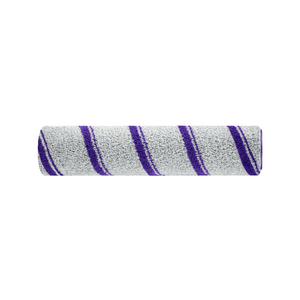

For the brushes, they often exist in two categories. For instance, we have nylon bristles that are durable and effective for sweeping up debris. Their flexibility allows them to reach into crevices and corners, ensuring a thorough clean.

On the other hand, we have rubber brushes that are particularly good for picking up pet hair and reducing tangles. Their design helps prevent hair from wrapping around the brush, maintaining efficiency and reducing maintenance.

Besides the brushes, the robot vacuum equally has filters.

First, it has HEPA filters which are made from fiberglass or synthetic materials. They are crucial for trapping fine dust and allergens. They also ensure that the air expelled by the vacuum is clean, making them a must-have for allergy sufferers.

Lastly, there are the foam filters, which often serve as pre-filters, capturing larger particles before they reach the main filter. This helps extend the life of the HEPA filter and maintains the vacuum’s performance.

Material Showdown: ABS vs. Polycarbonate, Nylon vs. Rubber

Not sure which materials really matter in your robot vacuum? Here's a side-by-side breakdown to help you decide:

ABS vs. Polycarbonate (Body Materials)

|

Feature |

ABS Plastic |

Polycarbonate |

|

Durability |

High |

Very high |

|

Flexibility |

Moderate |

Higher |

|

Scratch Resistance |

Good |

Excellent |

|

Best For |

Casual use, lighter devices |

Heavy-duty or premium models |

Nylon vs. Rubber (Brushes)

|

Feature |

Nylon Brushes |

Rubber Brushes |

|

Debris Pickup |

Good on dust |

Great for pet hair |

|

Tangle Resistance |

Lower |

Higher |

|

Floor Compatibility |

All types |

Ideal for hard floors & carpets |

|

Maintenance |

Needs regular cleaning |

Easier to maintain |

Wheels and Movement Components

Rubber is used for the wheels and treads to provide traction and durability. It ensures smooth movement across different floor types and helps the vacuum navigate obstacles.

Alternatively, plastic gears are also commonly used in the drive mechanism for their cost-effectiveness and durability. They are designed to withstand the stresses of regular use while keeping the vacuum’s manufacturing cost down.

However, for the wheels to stay in position, the metal bearings must come into play. This is because they are essential for ensuring smooth and reliable wheel movement. Furthermore, the bearings work to reduce friction and wear, contributing to the vacuum’s longevity and performance.

Finishing Materials

Assume the whole robot vacuum has been assembled, and what’s remaining is to apply some paint for the work to be done. For this to be completed, paint and coatings are applied to enhance the appearance and provide additional protection. These finishes help the vacuum look sleek and stylish while adding an extra layer of durability.

Besides the paints, adhesives are also an option. They are often made of synthetic resins and are used to bond various components. This ensures a secure fit and contributes to the overall structural integrity of the vacuum.

Conclusion

Robot vacuums are made from different materials, each picked to improve durability, performance, and safety. From the sturdy plastics and metals that form the body to the advanced electronic components and cleaning mechanisms, every material plays a critical role in making these devices effective and reliable.

Next time you’re in the market for a robot vacuum, for instance, at Narwal, consider the materials used in its construction. Knowing what materials are used can help you choose a vacuum that is effective, durable, and safe for your home.

FAQs

Are metal parts better than plastic in robot vacuums?

It depends on the part. Metal components like aluminum or stainless steel are stronger and more durable, making them ideal for structural or load-bearing areas. However, plastics like ABS are lightweight and cost-effective for the outer shell without sacrificing performance.

Which robot vacuum materials resist drops and impacts best?

Polycarbonate and ABS plastic are both impact-resistant. Among them, polycarbonate is generally tougher and better for homes with kids or pets where bumps and drops are more likely.

Do rubber wheels protect wooden floors better?

Yes. Rubber wheels offer better grip and cushioning, making them gentler on wood floors compared to hard plastic. They also help reduce scratches and improve traction on smooth surfaces.